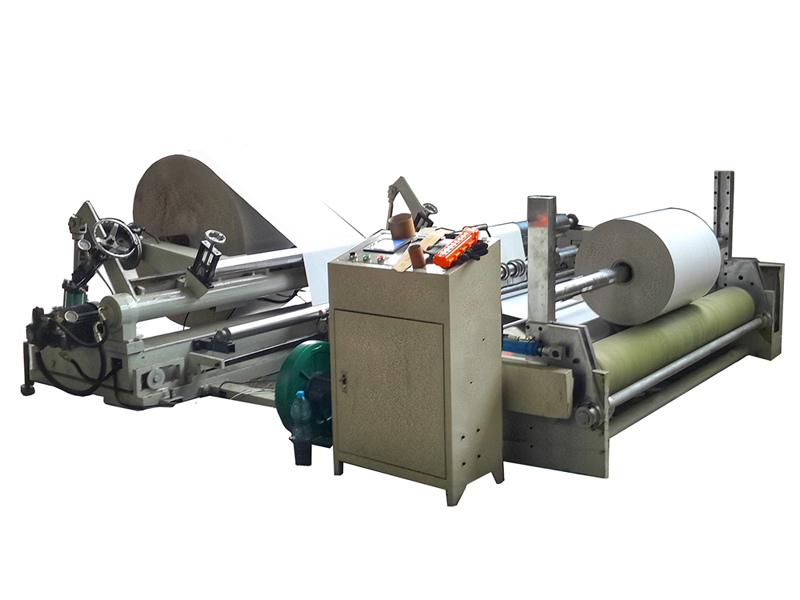

Slitting rewinding machine is used to slit the big paper rolls into small paper rolls , then rewind them. The hydraulic shaftless paper holder automatically loads and unloads the original paper (tray), which is easy to operate the slitting rewinding machine. Equipped with rubber arc-shaped sticks, the paper tray will automatically peel off after slitting, no need to beat. The external winding structure ensures that the paper tray is strong and compact after slitting, and the tension of the tube is correspondingly increased. As the one of slitting rewinding machine manufacturers, we would optimize the brake system control device to make the data accurate and stable during operation adjustment. Excellent cutters and structure ensure high precision of the paper tape of the slitting paper tray.

Equipped with an automatic rectifying system, the slitting rewinding machine adjusts the paper into the center position in real-time. With an electrical control system, the paper-slitting rewinding machine can produce productions at a much higher speed. Hydraulic shaftless paper holder, easy and fast to load paper. Electronically controlled hydraulic deviation correction, high precision. The suspension tension system keeps the tension constant. Heavy-duty slitting components, better slitting quality. Frequency conversion control synchronous belt drive, strong power, and lower noise. As one of innovative slitting rewinding machine manufacturers, we adopt new technology, so that the rewinding does not stick, and the paper roll spacing is 1-2mm. Single-group ground roller rewinding, low center of gravity, easier to unload paper.

Hydraulic paper stand, easy to load paper roll.

Automatic rectifying system, small tolerance.

Suspended tension system. Keep the paper slitting and rewinding machine in a steady performance.

Separate the rolls with Min. 1-2mm distance to avoid adhesion.

Single bottom roller rewinding system of paper slitting and rewinding machine, easy to unload.

A paper rewinding & rewinding machine is used for cutting paper rolls before making paper corners. Cut base paper roll and reroll it to the required width.

Paper slitting rewinding machine to the whole roll or the whole sheet of raw materials for fixed-length slitting processing, such as plastic packaging materials, packaging cartons, steel sheets, film, leather, wood chips, etc. for slitting and processing, are used for fixed-length slitting control.

Slitter fixed-length slitting control is divided into static and dynamic slitting two: in the set, length to arrive at the exact stop, and then static slitting processing, slitting after restarting the operation; in the set length to arrive, without stopping the slitting signal, paper slitting machines in the raw material movement process dynamic slitting processing.