Resources

Contact Us

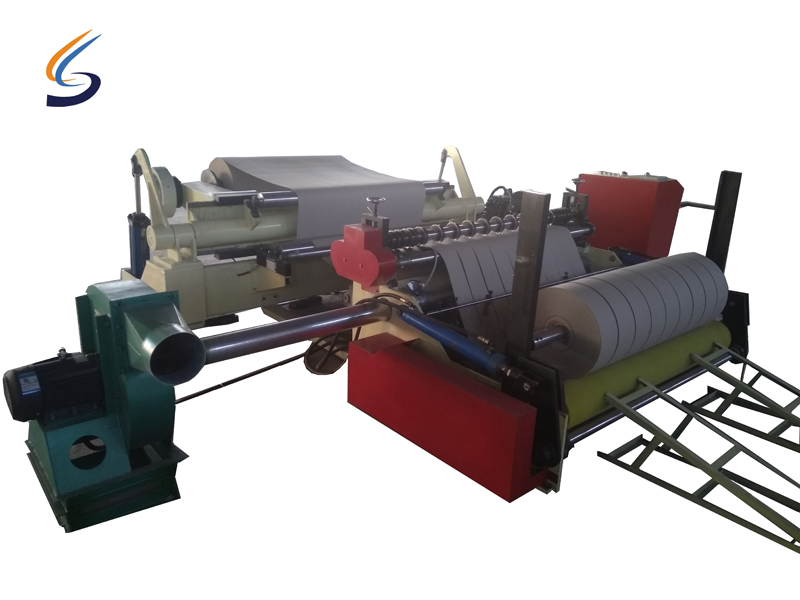

Paper Slitting and Rewinding Machine is a specialized equipment for paper and film, which may have damage or broken yarns inside and uneven edges on both sides. The packaging paper must be the edge of the unwinding machine.

Add lubricating oil according to the technical document requirements of the equipment;

There should be a gap between the shafts of the longitudinal device, and the gap size should meet the requirements of the technical documents of the equipment;

Place the piston rod of the device in the non-working position;

Before assembling the paper slitter rewinder machine, check the product quality certificate and the inspection quantity: full inspection. Inspection method: check the certificate and inspect the equipment.

A person in charge must arrange routine maintenance for the paper slitting and rewinding machine, and must ensure that the workers are familiar with the structure and performance of the machine tool while keeping it safe.

The tip of the paper slitter rewinder machine blade must be kept sharp. When the blade tip is dull or damaged, it should be polished, repaired or replaced in time. When multiple people operate, the person in charge must command, and cooperation must be coordinated.

The workpieces cut with the paper slitter rewinder machine must be placed steadily. Do not stack too many, and do not stack on the aisle. The scraps and waste materials should be sorted out in time, and the site should be kept clean.

The length of the waste paper and core tube is accurate, and the small car does not push the core tube to the corresponding position behind the front rail after the core tube is under the front rail, causing the core tube to accumulate in the front section, and the automatic upper pipe stops. The cause of the abnormality is unknown (there is no abnormality in the instrument and control), and the solution is to manually upper the pipe in this batch, change the blade online, change the waste paper order down, or change the width ±1-2mm, and then reset, and subsequent batches will automatically connect the pipes.

The blade change is correct, the core tube has reached the ready position, and the sensing limit switch also senses the core tube, but it does not start to automatically connect the pipe. The solution is to reset, manually upper the pipe in this batch, change the blade online, and check whether the limit switch near the position of the pushing car is interfered by the damaged paper. After checking it, start the machine, accelerate, and then reset, it should be okay.

The operator connected the pipe too quickly without paying attention, with a tube in the track, and then reset and cleared the data, and then automatically connected the next batch of core tubes, causing the pushing car motor protection alarm. Don't panic, after the paper is removed, take out all the core tubes in the track, and manually set the pushing car to the initial position on the inner touch screen to resolve the abnormality.

The paper slitter rewinder machine must be operated by fixed personnel of the packaging machinery and equipment, and be familiar with the steps of starting up and making bags. Simple instrument adjustments and parameter changes can be made; instrument adjusters must meet the strict requirements of the manufacturer.

Related Products

Related News