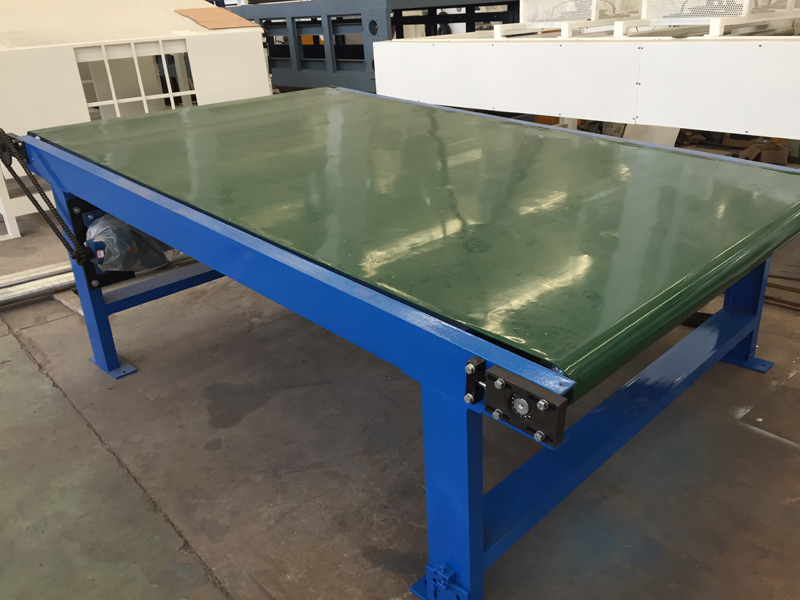

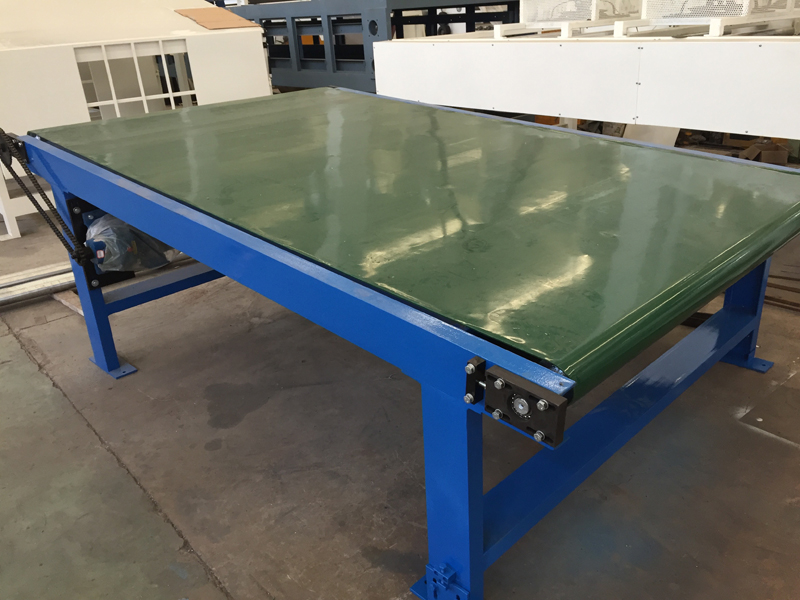

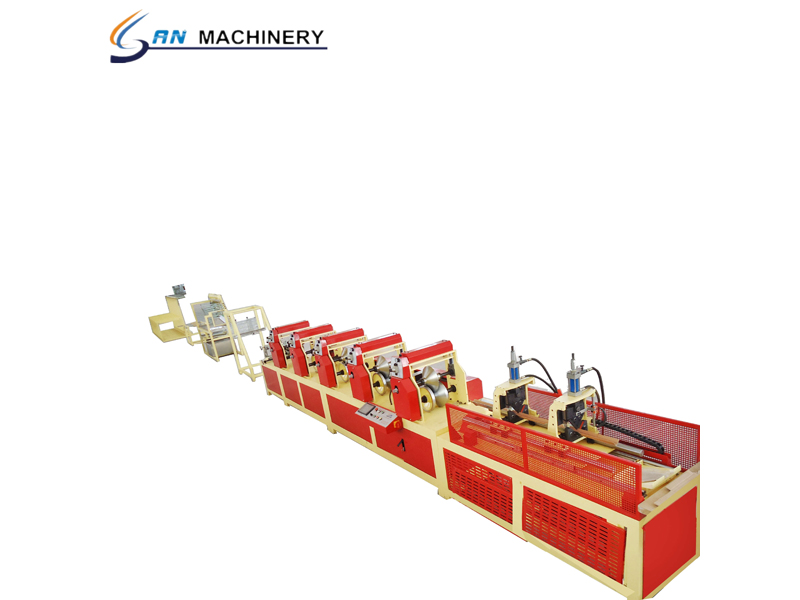

The production line is applied to produce honeycomb paper core and honeycomb paper panel. The line is automatic from raw material roll to the finished honeycomb paper panel. from paper goes into cardboard goes out, it is all completed in a fully automated production line. Only 2 to 3 operators needed, high paper utilization, advanced technology.

This device is equipped with two sets of glue roller that can produce two different honeycomb core size cardboard use two cladding. Use man-machine interface, PLC control, high degree of automation. Greatly improve production efficiency.